four point bending testing machine|4 point bending calculator : trade A bend tester is configured to your requirements by our application engineers with a three or four point bend test fixture, the correct controller, and a deflectometer if you would like to measure sample deflection directly and . web3 dias atrás · Atualizado 29 fevereiro 2024. 2024 é um ano bissexto, o que significa que temos um dia a mais no calendário. Mas por que precisamos deste dia? Bem, um dia é o .

{plog:ftitle_list}

WEBDescubra a receita de bolo massa de chantilly para fazer em 20 minutos. Juntar todos os ingredientes na bacia da batedeira, bater por aproximadamente 5 minutos. Colocar em .

Examples of bend tests include applying three-point or four-point flexural forces to concrete beams, plastics, and composites to determine the amount of flexural force and strength .

Universal testing machines equipped with bend fixtures are used to calculate .The Pavetest Servo-pneumatic Four Point Bending System (4PB) is a servo-pneumatic testing machine utilizing digital control of a high performance servo valve to provide accurate loading wave shapes up to 60 Hz.A bend tester is configured to your requirements by our application engineers with a three or four point bend test fixture, the correct controller, and a deflectometer if you would like to measure sample deflection directly and .While it is easy to imagine why bend testing needs to be performed on rigid materials like plastics (ASTM D790) and concrete (ASTM C1609), in reality bend test applications are common in a variety of industries. Universal testing .

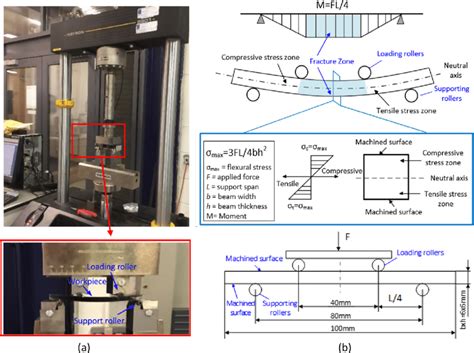

EN1288-3 gives a schematic description of the test setup for the four point bending test (Fig. 1). This description is a vastly simplified version of the actual testing equipment used in most industrial applications and labs. .

four point bending test setup

four point bending test procedure

Universal testing machine load frames come in single or dual column configurations and are available in force capacities up to 2,000 kN. . Wood and composites are most commonly tested with the 4-point bend test. The 4 .1940s flexural test machinery working on a sample of concrete Test fixture on universal testing machine for three-point flex test. The three-point bending flexural test provides values for the modulus of elasticity in bending, flexural stress, flexural strain and the flexural stress–strain response of the material. This test is performed on a universal testing machine (tensile .4 Testing Machines w+b Materials Testing Systems Closed-Loop Controlled Rotary Bending . • Fast and easy test set-up • Four-point bending type providing constant bending moment over the entire specimen length • Introduction of low torque moment through low friction spindleFour Point Bending. In this lab, a Four-Point Bend Test is performed on ABS plastic beams from the PASCO Structures System and the Flexural Elastic Modulus for the material is calculated. . Materials Testing Machine. This is the assembly-only version; measures force and displacement for various materials as the materials are stretched .

Universal testing machines equipped with bend fixtures are used to calculate flexural modulus, flexural strength, yield point, and more. . Four-point bend fixtures: Configuration of flexural . For the 3-point bending test, the graph shows the force (load) exerted by the loading nose versus central displacement recorded by the testing equipment. For the 4-point bending test, the results show the force versus central displacement (note the full load on the bar was 2× force). Similar patterns are noted for both types of flexure tests.w+b Materials Testing Systems Closed-Loop Controlled Rotary Bending Fatigue Testing Machines Series UBM with Load Cell instead of Dead-Weights The full line of rotary bending testing machines is also available with incorporated Force Transducer with digital closed loop force control and application software. In this case is the rotary bending machine is equipped .

Four-point bending test are widely used to investigate the strength and toughness of FRC [13], [14].The flexural toughness of FRC has became a key parameter in engineering design and construction inspection [13], [14], [15].American Society for Testing and Materials (ASTM) C 1018 [13] and Japan Society of Civil Engineers (JSCE) SF-4 [14] testing methods . 1.2.5 Bending test. The three-point as well as four-point bending tests are conducted for measuring the deflection and bending strength of fiber-reinforced polymer plastics. . The loads may be applied manually by hanging weights on the beam or by a testing machine. Deflections are measured by a dial gauge placed underneath the beam. From the .

four point bending test pdf

Four-point bending tests were conducted on the PVA-ECC beams using the 200 kN Tecnotest Flex machine in accordance with standard ASTM C1609 (ASTM, 2006).Instead of three-point bending tests, four-point bending tests were performed so as to investigate the flexural behavior in the pure bending region.Easy to install, the 3 point fixture can be modified with an optional conversion kit to provide a 4 point bending conversion. Lower anvils are adjustable to accommodate specimens of different spans. Deflection of the specimen can be measured either through crosshead displacement, or for more precise measurement use the mid span direct .

The main equipment used in a bend test is a universal testing machine or a specific bend testing machine. Other equipment includes the necessary supports and anvils. Why use a 4 point bend test? The 4-point bend test is used as it provides a constant moment region in the material, and it can provide more accurate measurements of the material .Easy to install, the 3-point fixture can be modified with an optional conversion kit to provide a 4-point bending conversion. Lower anvils are adjustable to accommodate specimens of different spans. Deflection of the specimen can . EN1288-3 (Glass in building—Determination of the bending strength of glass—Part 3: test with specimen supported at two points (four point bending), 2000) describes the four point bending test for the determination of glass strength. The failure stress is calculated from the vertical force of the testing machine. To determine the difference between .Fig.1(a) shows a guided bend test jig that uses a male and a female former, the commonest form of equipment Fig.1(b) shows a wrap-around guided bend test machine that works on the same principles as a plumber's pipe bender. The .

friction facts belt test

Equipment Monitoring ; Software & Monitoring . High-frequency, low-force four-point bend tests of small extremity implants allow medical device developers to get products to market faster. Higher frequency testing may deliver a five-fold improvement in time to market, depending on the specimen. . 4-Point Bend Test Demo: An MTS Acumen test .A three-point flexural test performed on an Instron universal testing machine. Reproduced with permission from McKeen, L. W. (2015). Introduction to creep, polymers, plastics and elastomers. . It is generally recommended to perform four-point bending tests, as a larger portion of the sample is subjected to the maximum bending moment . TestResources manufactures and supplies universal test machines, tensile testers, dynamic testing machines, and much more. Call us today (800)430-6536. . The three-point bending flexural test measures a material’s resistance to bending forces by applying load at the midpoint of a beam supported at both ends. It’s essential for determining .Equipment Monitoring ; Software & Monitoring Solution Finder Search by Test Material, Test Type, or Test Standard to find relevant products fast. . 4-Point Bend Testing See demo of small scale 4-point bend testing. Watch Video Case Study .

The Stand Alone Four Point Bending Beam Machine uses advanced servo pneumatic technology and a high-speed digital data acquisition and control system together with user-friendly software. During testing both graphical and tabular data are displayed on screen and test data is stored to disc in Microsoft® Excel® compatible format. Table 4 shows the values for each of the four placing options of the beam in the testing machine. Thus, the transversal side with the wood grain type A is first on top (compressive stress) and then on the bottom (tensile stress) by rotating 180° around the center axis. . In the four-point bending test, in addition to the elastic modulus and .Easy to install, the 3-point fixture can be modified with an optional conversion kit to provide a 4-point bending conversion. Lower anvils are adjustable to accommodate specimens of different spans. Deflection of the specimen can be measured either through crosshead displacement, or for more precise measurement you can use a mid-span direct .

Flexural testing is used to determine the flex or bending properties of a material. Sometimes referred to as a transverse beam test, it involves placing a sample between two points or supports and initiating a load using a third point or with two points which are respectively call 3-Point Bend and 4-Point Bend testing.Easy to install, the 3 point fixture can be modified with an optional conversion kit to provide a 4 point bending conversion. Lower anvils are adjustable to accommodate specimens of different spans. Deflection of the specimen can be measured either through crosshead displacement, or for more precise measurement use the mid span direct .

The Comprehensive Materials Testing System includes the Materials Testing Machine (ME-8236) and all the accessories needed to investigate compression and tensile testing, column buckling, three and four-point bending, shear testing, and stress lines with photoelasticity. In addition, the Comprehensive System includes a sturdy, plastic base with .

four point bending test formula

Série de Animação Francesa

four point bending testing machine|4 point bending calculator